Textile Item Number: K2.162 from the MOA: University of British Columbia

Description

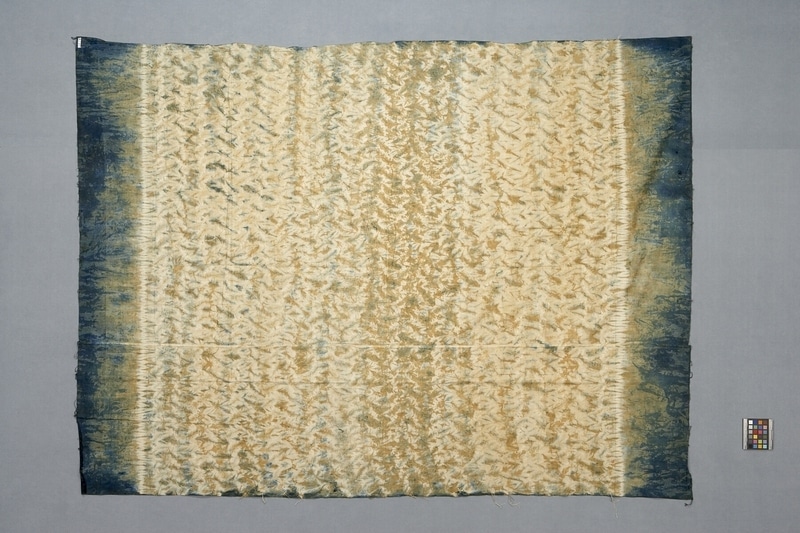

Textile composed of two pieces of cotton damask with a leaf pattern sewn together. The cotton textile is tie-dyed with indigo and orange-brown dye to form a mottled pattern at the centre and bands of dark greenish-blue at the ends. The ends are unfinished.

History Of Use

Gara cloth for men's robes and women's wraps. Gara is a form of indigo dyeing; name comes from gara leaves that are used to create the dye. Previously gara dyeing was only done by women but is now done by both men and women; men are considered experts in sewing and tying gara. However certain dye patterns, such as Kolinge and Cloud, are done exclusively by women. Makers of gara cloth have always had high status and many makers cater to the wealthy by creating specially designed cloths and garments. Production of gara peaks during the dry season (October-April) because the weather allows for airing and drying, and there are a number of festivals that require new outfits. New designs are spread rapidly each season and are popularized by officials and their families, who wear them at formal events. In Sierra Leone today, “gara” widely refers to any dyed cloth.

Specific Techniques

Gara leaves are the main ingredient in the dye bath; others include bark, roots, berries, ash, and other leaves. Average dye fermenting is seven to ten days, but can be hurried with the addition of caustic soda and commercial dye, or kola nuts. A fresh dye vat and multiple immersions are necessary to build colour on indigo cloth. Designs are made on cloth with wax-resist, block-stamping, and tie-dyeing. There are four styles of pattern: Taka, Scattered candles, Cloud, and Kolingie. Taka consists of the cloth being folded into pleats and then having them tied together with a cord, resulting in a longitudinal stripe pattern. Scattered candles involves the bristles of a short handheld broom getting dipped in hot wax and then having drops scattered over the cloth. Cloud style has the fabric pulled into cloud-like puffs; it is more difficult to make as the fabric comes out of shape as the dyer moves their fingers. Kolingie involves a rice or cassava paste being applied to the fabric while still wet; a pattern is made by scraping a comb in semi-circles or lines. When the paste is dried the cloth is dipped in the dye, left to dry, and then the paste is washed off. The light blue colour produced is called fente. For all pattern styles, once the cloths are dried the surfaces are beaten on a wood log with wood clubs to give them a sheen.

Item History

- Made in Sierra Leone ?

- Owned by Abi Jones before January 13, 1968

- Received from Abi Jones (Seller) and Walter C. Koerner (Funding source) on January 13, 1968

What

- Name

- Textile

- Identification Number

- K2.162

- Type of Item

- textile

- Material

- cotton fibre, dye and indigo dye

- Manufacturing Technique

- tie-dyed

- Overall

- height 123.5 cm, width 166.0 cm

Who

- Culture

- West African

- Previous Owner

- Abi Jones

- Received from

- Abi Jones (Seller) and Walter C. Koerner (Funding source)

Where

- Holding Institution

- MOA: University of British Columbia

- Made in

- Sierra Leone ?

When

- Ownership Date

- before January 13, 1968

- Acquisition Date

- on January 13, 1968

Other

- Item Classes

- textiles

- Condition

- good

- Accession Number

- 0130/0026